When to Choose Physical Destruction vs Logical Wiping for Retired Devices

Deciding between physical destruction and logical wiping for retired devices affects data security, compliance, and downstream reuse. This article explains how data remanence, sanitization standards, lifecycle needs, and logistics influence whether to wipe, recycle, refurbish, or destroy hardware, helping organizations match disposal methods to risk profiles and regulatory obligations.

Retired devices carry persistent data risk until properly handled. Organizations must weigh technical sanitization, legal compliance, and operational logistics before deciding whether to perform logical wiping or to apply physical destruction. Factors such as data classification, potential for reuse or refurbish, certification requirements, and evidence for audits shape the right approach. This article outlines practical criteria and trade-offs so IT teams and asset managers can align disposal choices with security policies and lifecycle plans.

What is data sanitization and remanence risk?

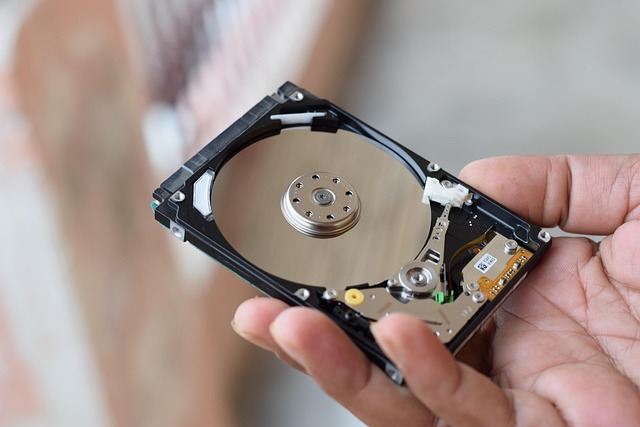

Data sanitization refers to actions that render stored information unrecoverable by intended methods. Remanence is the residual magnetic or electronic trace that can remain after attempted erasure. Different media and storage technologies—magnetic HDDs, SSDs, flash modules—exhibit varied remanence behaviors, which affects whether software-based wipe methods are sufficient. Security teams should classify data by sensitivity and evaluate the residual risk before deciding on a wiping procedure or opting for physical destruction to eliminate remanence concerns.

When is logical wipe or imaging appropriate?

Logical wipe methods include overwriting, secure erasure commands, and reimaging devices with known-good images. These techniques are useful when devices are to be reused, refurbished, or redeployed within controlled environments. Logical wiping preserves hardware value while addressing many security concerns, provided the process includes verification steps (overwrite passes or cryptographic erasure) and logging. For SSDs and devices with built-in encryption, certified erase commands or crypto-erase approaches can be effective, but verification must consider device-specific behaviors and firmware quirks.

How do backup, reuse, and refurbish fit in?

If an organization plans to reuse or refurbish equipment, preserving hardware integrity is important. Before wiping, ensure backup and imaging of any data required for business continuity. Imaging can capture system states for redeployment while secure erase routines clear user data. Reuse and refurbish paths reduce waste and support recycling goals, but they also demand robust sanitization records and possibly certification to satisfy internal security policies or third-party purchasers. Properly documented workflows help maintain chain-of-custody and minimize operational disruption.

What do compliance, certification, and audit require?

Regulatory frameworks and contractual obligations often dictate minimum sanitization standards and proof for disposal actions. Some sectors require documented sanitization logs, third-party certification, or destructive evidence when high-sensitivity data were stored. Auditors typically look for policy-aligned processes, traceable records of wipe or destruction, and certification of service providers when outsourcing disposal. Matching the sanitization method to compliance requirements is essential: logical wipes may suffice for lower sensitivity data, while certified destruction could be mandated for regulated datasets.

How do logistics, lifecycle, and disposal interact?

Logistics and asset lifecycle planning influence whether devices are routed to internal IT, a certified refurbisher, or a destruction service. Transportation, inventory tracking, and secure storage during transit must be part of the plan. Disposal and recycling partners may offer remanufacturing or material recovery, which favors logical wiping to maintain component value. Conversely, end-of-life disposal in your area might be faster via physical destruction followed by materials recycling. Consider environmental disposal regulations alongside security needs to ensure compliant, sustainable choices.

When is physical destruction the right choice?

Physical destruction—shredding, degaussing, or chip-level crushing—provides a high-assurance solution when devices contained highly sensitive data or when remanence risks and verification challenges make logical wiping inadequate. It is often chosen when hardware will leave the organization for recycling or when certification standards require irreversible destruction. Physical methods eliminate the need to rely on device firmware or overwrite verification, simplifying audit trails in some contexts. However, physical destruction prevents reuse and reduces asset recovery value, so it should be balanced against sustainability and lifecycle considerations.

Physical destruction and logical wiping both serve valid roles in device retirement. Choosing between them requires assessing data sensitivity, media type, compliance obligations, potential for reuse or refurbish, and logistical constraints. Implement standardized policies that document the decision criteria, verification steps, and audit logs to ensure consistent handling across the lifecycle. Clear records of backups, imaging, sanitization, certification, and disposal actions will support security reviews and help manage both risk and asset value.